|

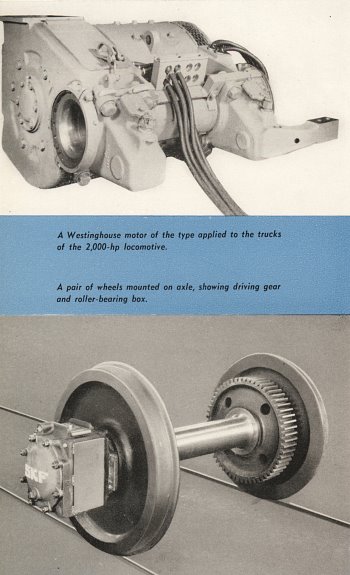

injection system is of the unit injector type with an injection pump at each cylinder. A motor-driven pump transfers fuel oil from the storage tank under the locomotive frame through a series of cartridge type filters, and charges a fuel line from which the fuel injection pumps take their supply. Lubricating oil is circulated by means of a posi- tive displacement gear pump which is chain- driven from the crankshaft. The lubricating oil supply is contained in the bed plate sub-base. Before reaching the engine, the lubricating oil passes through a suction strainer, cooling radi- ator, a by-pass absorbent type filter and a metal- edge full flow filter mounted on the engine. Each engine has its own cooling system. Ra- diator assemblies, for cooling both water and lubricating oil, are located under the engine com- partment roof, the cooling water being circulated by means of chain-driven centrifugal pumps. Thermostatically controlled shutters are installed in the engine compartment side walls. Two Westinghouse Type 480-B generators fur- nish power to the four traction motors, one gener- ator supplying power to motors number one and two which are connected permanently in series, and the other supplying power to motors number three and four, likewise connected in series. The generator frame is supported from the en- gine bed plate and the armature is connected directly to the crankshaft. The armature shaft has one self-aligning roller bearing. A multiple V pulley, on an extension of the armature shaft, drives the auxiliary generator-exciter set which is |

|

8 |