|

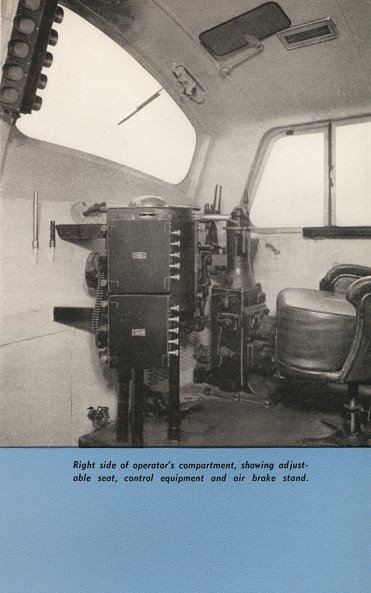

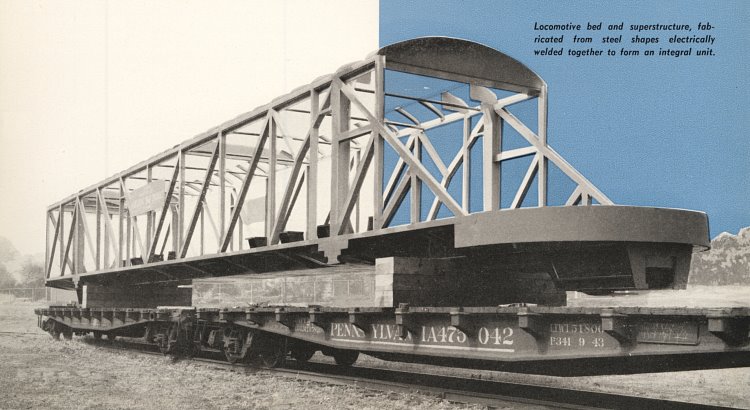

are provided on the right and left hand sides of the operator's compartment. The diesel engines are Baldwin, eight-cylinder, normally aspirated four-cycle type developing rated power at 625 r.p.m. The cylinders have a 12 3/4-inch bore and a 15 1/2-inch stroke. The engine bed and frame are weldments of steel, giving a rigid structure of uniform material with strength built in where it is needed. The frame is integral with the upper part of the crank- case and this, in turn, is bolted to the lower part of the crankcase which is a part of the bed struc- ture. The cylinder liners, housed in the frame, are of the removable sleeve type of centrifugally-cast nickel iron. The wearing surface of each liner is honed within close tolerances and then chrome plated to give longer life to liners and rings and to minimize the chance of piston seizure. The crankshaft is a heat-treated, solid steel forging, drilled for pressure lubrication, with 8 3/4- inch main bearing journals and 8 3/8-inch crank pins. Main bearings are removable without lifting the crankshaft. Drop forged, alloy steel connecting rods of the four-bolt type are used. The cylinder heads, embodying the turbulence combustion chamber, are separate castings of air furnace iron. The pistons are cast from heat- treated aluminum alloy and are fitted with five compression rings and three oil rings. The valves are alloy steel, seated in the cylin- der heads and actuated by rocker arms. The fuel |

|

|

7 |