|

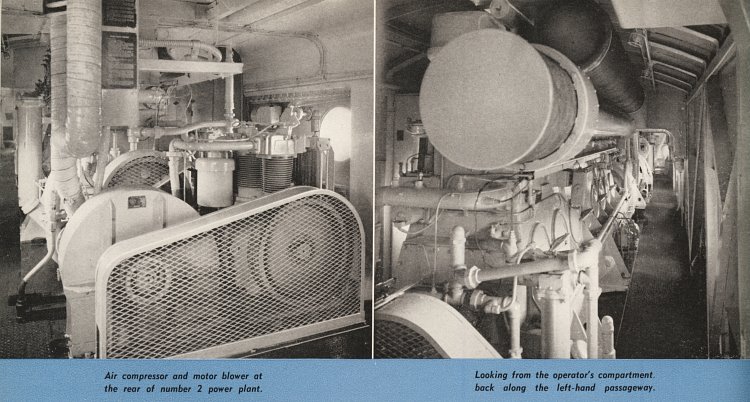

The "A" unit, described in this article, has a total weight of about 381,000 pounds and is car- ried in two six-wheel trucks. The starting tractive force, at 30% adhesion, is 76,200 pounds. The total length of the unit, over coupler knuckles, is 80 feet; the distance between truck center pins is 49 feet; and the total wheel base is 64 feet 4 inches. The two power plants consist of 1,000-hp, Bald- win diesel engines, direct-connected to Westing- house generators. Traction motors and electrical control equipment are products of Westinghouse Electric Corporation. The two 1,000-hp power plants are located one ahead of the other, on the center line of the loco- motive, with the two generators facing each other. An air compressor is located at the rear end of each engine and the necessary air reservoirs and intercooler are mounted beneath the underframe of the locomotive. This system provides air for operation of the brakes, pneumatic control equip- ment and horn. Starting the diesel engine is ac- complished by motoring the generator, using current from the batteries. Blowers for cooling the traction motors are V-belt driven from the engine crankshaft. Fuel and water tanks are suspended beneath the loco- motive underframe. Motor driven fans, taking current from the main generators, provide air for the engine cooling system. Radiator shutters are thermostatically controlled, eliminating the human element and |

insuring proper operating temperatures for the diesel engine, regardless of whether the locomo- tive is operating in desert heat or arctic cold, hauling a 50-car train or running light. The engineman's operating compartment is lo- cated in the nose of the "A" unit and at the oppo- site end is the steam heat generating equipment for cab and train heating. The underframe of the locomotive is a welded structure fabricated from steel plates and shapes. The principal longitudinal and transverse mem- bers are I section. The superstructure is of the truss type, welded to the underframe to form an integral unit, and the steel cab sheets are welded to the framing. Hatches in the roof permit the removal of either power plant, and added maintenance conve- nience is provided by hinged covers which permit piston and liner removal without the necessity of taking off the main hatches. A hatch is provided for removal of the steam generator. The operator's compartment has fixed front win- dows and combination hinged and sliding side windows, all fitted with shatterproof glass. Front windows are equipped with windshield wipers, defroster fans and sun visors. The cab floor is cov- ered with linoleum and comfortable heat is main- tained, even during the coldest weather, by means of steam radiators. Upholstered, adjustable seats |

|

6 |