16 |

BALDWIN LOCOMOTIVES |

|

of the Diesel affords a distinct economy in fuel. On the other hand, fuel costs are not as important as some other costs; and—more important

—fuel economies are far less certain than savings in interest, amortization, taxes, and repairs. Why? Because when one looks to the future, it is reasonable to assume that with our enormous supplies, the price of coal will remain relatively low for generations to come. But the sources of flush production of our oil could dry up in a relatively few years, and an increase in the demand for the various crude oil products might double or treble the price of them within a generation. So that anybody who buys a Diesel locomotive, counting upon the constant repetition into the indefinite future of the fuel economies of today, is taking a gamble. I don't say that they won't exist, but the probabilities are against it. I do say that the economies of the steam locomotive—of interest on a lesser investment, amortization of a lesser investment, taxes on a lesser investment

—those savings are real and can be counted on to continue.

Diesel Versus Steam Repair Costs

But the greatest source of disappointment will undoubtedly come from the cost of repairs. I hate to bring this out, with our good friend Roy Wright sitting right down here in the front seat. But not so long ago he and his able group published a booklet on "The Diesel in Railway Service." On one of the pages of this booklet they listed what the manufacturers claim for Diesel electric locomotives. The sixth of these claims reads as follows:

"The cost of maintenance is only a fraction of an equivalent steam locomotive."

I have seen studies of switching problems in which some Diesel manufacturers have treated maintenance as though it would be substantially the same for every year of operation. But you men all know that down at Eddystone in the last four years we have analyzed the repair costs of tens of thousands of

|

locomotives in every form of service. We have proved beyond peradventure of a doubt that there is an inexorably rising cost of repairs with the advancing age of any prime mover. With regard to steam this is so definite that we have cost curves from which we can predict within a few cents the probable cost of repairs per mile of a locomotive of any given horsepower, of any given age, with any given intensity of service.

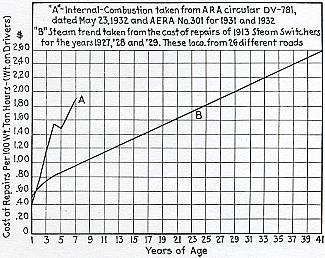

With regard to Diesel locomotives, of course, the data is meagre as compared with that for steam. The data which is available, however, has been published as an'appendix to the report of the A. R. A. Committee on Locomotive Construction. The report of May 23, 1932, covers a hundred odd locomotives from one to seven years old. I have had this reduced to a comparable basis on Slide No. 3 showing the cost of repairs per hour for a 100-ton locomotive, and you can read it forward and backward for a locomotive of any other size by simply taking the proportion that it bears to 100 tons; that is to say, a 60-ton locomotive per hour would be 6/10th of the cost shown at the given year of age.

Now the curve marked B is the curve which we derived from our study of 1913 steam switchers operated by 26 public service railroads in this country, locomotives all the way

Weight Per Hour of Internal-Combustion and Steam Switching Locomotives. |