|

articulated driving wheel trucks, all having cast steel frames furnished by General Steel Castings Corporation. The articulated trucks have side frames, crossties, pedestals, engine truck center pins, cab center plates and motor suspension supports cast integral. The frame pedestals are equipped with rubber insert pedestal gibs. The inner ends of the two articulated truck frames are connected by means of an articulated joint of the ball, socket and pin type, oil lubricated. The mo- tor suspension is of the bar type with spring- cushioned supports. Driving axles are of forged low-carbon nickel- steel, hollow-bored and mounted in SKF roller bearings. The multiple-wear driving wheels, 40 inches in diameter, are "Freedom" type wrought steel furnished by Standard Steel Works Division of Baldwin. The roller-bearing boxes are arranged |

for oil lubrication of bearings and pedestals, and are designed for future application of the Edison bearing temperature alarm system. Equalization for each articulated truck consists of a three-point support with four driving axles connected together on the side forming two points, while the third point is the engine truck center pin. A semi-elliptic spring rests directly on each driving box, the ends being connected to forged equalizing beams except at the ends where spring-cushioned links connect the system to the articulated truck frame. The four-wheel engine trucks (leading and rear) have hollow-bored axles of low-carbon nickel-steel, mounted in SKF roller bearings. "Freedom" wrought steel multiple-wear wheels, 40 inches in diameter, are used under the trucks. The nickel-steel frames have side members, tran- |

|

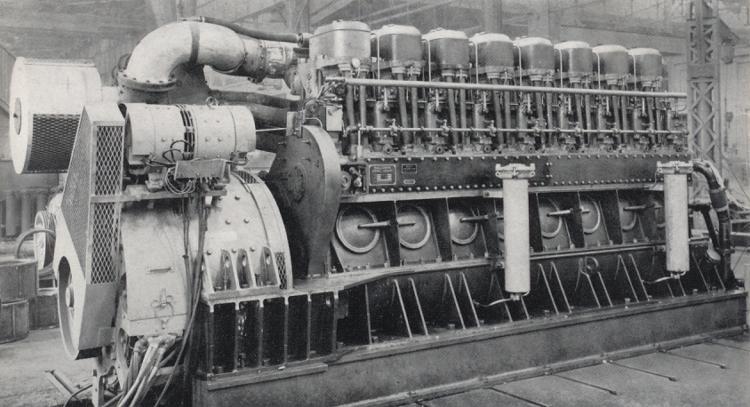

Shop view of one of the two 8-cylinder, 1,500 hp Baldwin-Westinghouse power units that make the new Diesel-electric the most powerful of its type in the world. |