3. Slow combustion gives low fuel

comsumption, low maximum

combustion pressure, absence

of smoke, lack of detonation,

shockless operation, quick

"pick-up" and smootb idling.

4. In general, this method of combus-

tion renders the engine less

sensitive to variations in fuel

oil characteristics, allowing it

to operate smoothly and satis-

factorily with any good grade

of diesel oil.

The fuel injection equipment is

of the Bosch type with an individ-

ual fuel pump for each cylinder

and a spray valve which enters the

side of each spherical combustion

chamber. Direct combustion oc-

curs in this chamber which is off-

set from the center line of the cyl-

inder and is entirely surrounded

by water jacketing. This results in

lower operating temperatures of

valves, pistons, piston rings and

cylinder liners, complete combus-

tion and advantageous lubrication

conditions.

The offset position of the com-

bustion chamber and the elimina-

tion of a central vertical spray

nozzle, permits the use of a large

single exhaust and a single inlet

valve for each cylinder. The use

of two valves, instead of four, sim-

plifies the valve gear and allows a

shorter and more compact cylin-

der block, as well as more space

for cooling water to circulate

where it is most needed.

Engine frame design incor-

porates new features which are ex-

clusive with De La Vergne. The

engine frame is a single rigid cast-

ing designed to obviate the neces-

sity for through bolts or tie rods.

This method of construction

makes possible a very rigid and

compact cylinder block casting.

Crankshaft bearing supports are

attached to the engine frame. This

arrangement, together with pre-

|

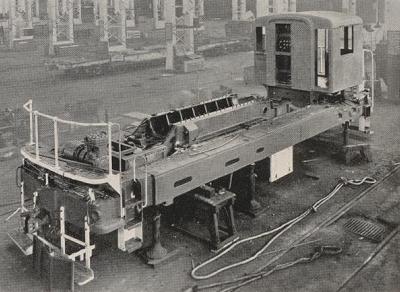

Underframe and Sub-Base Assembly.

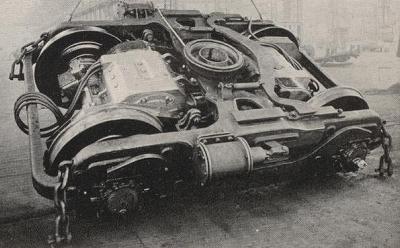

A Truck Complete with Motors,

Air Brake Cylinders and Brake Rigging.

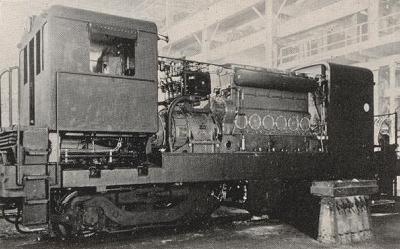

Locomotive with Entire Hood Removed,

Showing Accessibility of All

Parts of Engine and Electrical Equipment.

|