pad is inserted between the sub-base and the

main underframe to provide protection against

rail shock.

The De La Vergne Engine

The locomotive is powered with a De La

Vergne Model "VO," four-cycle, six-cylinder

solid injection, cold starting, full diesel engine

direct connected with the main and auxiliary

generators. It has a cylinder bore of 12 1/2

inches, a piston stroke of 15 1/2 inches and is

rated at 660 b.hp. at 600 r.p.m.

This modern De La Vergne design is backed

by the experience gained in forty years of

building solid injection oil engines and twenty

years of building solid injection diesel engines.

De La Vergne's association with oil engines

dates back to the year 1893, when this com-

pany obtained the sole American rights to man-

ufacture the English Hornsby-Ackroyd engine.

The first solid injection diesel engine produced

in the United States was built by De La Vergne

in 1917.

The engine of locomotive 62000 is unique in

that it contains a number of features which are

new in railroad diesel practice, features which

have definite advantages in operation and

maintenance, resulting in lower costs and in-

creased profits.

An exclusive De La Vergne feature of major

importance is the spherically shaped combus-

tion chamber which is cast integral with the

cylinder head and is connected with the cyl-

inder combustion space by a throat.

The contour of the chamber and throat are

such that air, rushing in from the cylinder dur-

ing the compression stroke, creates a turbu-

lence which is controlled in such a way that

the air is thoroughly mixed with the atomized

fuel. This thorough mixing results in a rel-

atively slow sustained combustion period so

|

more important of which may be summarized

as follows:

1.It permits a longer injection period than is pos-

sible in other locomotive diesel engines of

similar size, resulting in low fuel injector

opening pressures and low fuel injection

pressures. The injection pressure of the De

La Vergne engine is about 3300 pounds as

compared with a direct injection pressure of

6000 pounds or more found iť other types.

The De La Vergne firing pressure is about

650 pounds, a distinct gain over other types

where pressures range from 730 to 1000

pounds.

2. The orifices of the multiple spray nozzle can be

made unusually large, thus minimizing the

tendency to clog. Larger openings combined

with lower injection pressure and the conse-

quent lower velocity of the oil, give greatly

reduced erosive action at the nozzle.

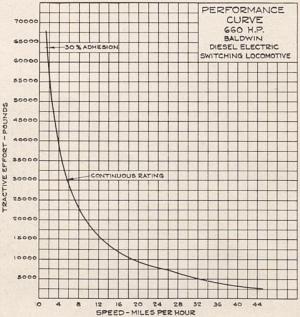

Tractive Force Curve for Speeds Up to

45 Miles Per Hour.

|