and no locomotive was ever supposed to run over more than one division. And yet today we run locomotives from 500 to 1000 miles in continuous service. While new locomotives are built better, still it remains true that thousands of old locomotives could have been run over two or three divisions, could have made two or three times as many miles as they did, if only there had been a belief in the human organization running them that they could do it. I have seen a number of steam switchers in this country that are making 7200, 7500 and even 7700 hours of service a year. With a certain amount of time lost for ashes, fuel, water, and so forth, a modern steam switcher can make 24 hours a day, six days a week, just as well as a Diesel locomotive.

One-Man Operation Also Available In Steam

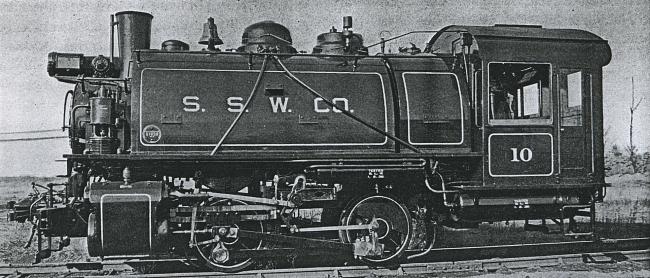

Another and real advantage of the Diesel locomotive has been its mechanical availability for one-man operation. Where such an operation is safe and permitted by law and working arrangements, it has meant a real economy. But we have just proven, down at Eddystone, that this economy can be matched in steam power. Slide No. 4 shows you the first automatic oil-fired steam locomotive.

It is a little saddle tank locomotive which we

|

built for our own Standard Steel Works at Burnham. Without discussing certain features on which we contemplate patent application, the fundamental idea is perfectly simple. The fire of this locomotive is regulated by the steam pressure. It never pops, because, when the steam pressure reaches a few pounds below the blow-off point, the fire automatically reduces. We can set the points at which the fire reduces and again increases within a substantial work-' ing range. In this locomotive now before you the fire has three positions; low, intermediate, and high; but we can make it four or five, if necessary. No steam and no fuel is wasted. At the low flame this burns about four gallons of bunker C oil per hour, costing less than 15 cents. The engineer does not have to think about keeping up steam at all. All he has to do is to run the locomotive. Our records indicate so far that in this locomotive we have used only about 35 per cent of the B.T.U.'s we used doing the same work in our old coal-fired switchers. We have even put roller bearings on this locomotive partly as a contribution to lubrication, and partly to avoid time out for adjusting driving boxes. In other words, we have tried to produce a little steam switcher the wheels of which never have to be dropped except for flange wear. Our idea is that the fuel supply should be sufficient for 24 hours'

|